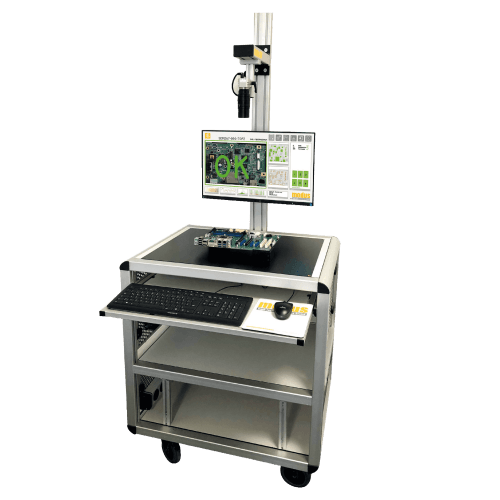

modusAOI MCS42-SEL-AL

Kamera-Inspektion

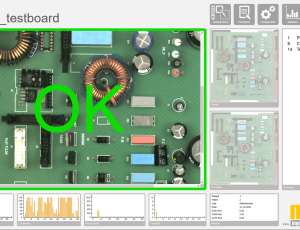

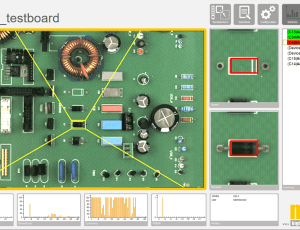

Das MCS42-SEL-AL ist ein kostengünstiges kamerabasiertes AOI-System. Diese Lösung ist für die wirtschaftliche und flexible Inline und Online-Inspektion der verschiedenen Produktionsprozesse optimiert. Das kleine und preiswerte System verfügt über eine 42 Megapixel, hochauflösende Industriekamera und einen PC mit der leistungsstarken modusAOI Software, in deren Entwicklung zwei Jahrzehnte Berufserfahrung stecken.

Produkt-Merkmale

-

Einziges System für die Inspektion von Objekten.

-

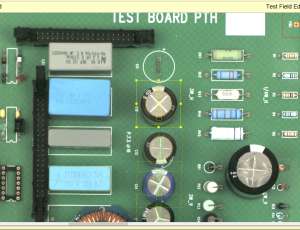

Kombination verschiedener Applikationsaufgaben im THT-Bereich, die vor einem Wellenlöt- oder Selektivlötofen stattfinden.

-

Typische Prüfungen umfassen die Bestätigung des mechanischen Zusammenbaus, das Vorhandensein, die Platzierung und die Ausrichtung von Steckern, Aufklebern und Befestigungen sowie das Lesen von Barcodes und Data-Matrix-Codes.

Technische Informationen

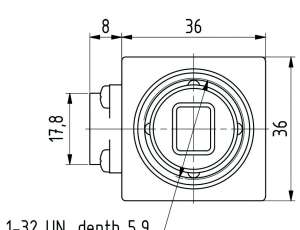

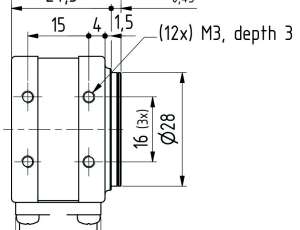

Kameraeinheit C42

-

Auflösung 42 Megapixel (7716 x 5364 Pixel)

-

Bildseitenverhältnis 3:2, Pixelgröße (am Objekt) abhängig von Brennweite und Arbeitsabstand

-

RGB-Farbfilter auf CMOS-Sensor

-

Farbtiefe 24 Bit

-

Lichtquelle

-

Keine externe Beleuchtungseinheit erforderlich. Funktioniert mit Umgebungslicht in der Produktionsumgebung.

-

Automatischer Weißabgleich und automatische Belichtung sorgen für stabile Tests

-

Objektiv

- 1:1,4 - 25,5 mm, andere Objektive optional (C-Mount)

Inspektionsbereich mit Standardobjektiv

-

Betriebsbereich bis zu 420 mm x 300 mm

-

Mindestabstand der Kamera 280 mm

-

Test Geschwindigkeit

- Bildaufnahme einschließlich Analyse: typischerweise 2-4 Sekunden

System PC

-

Intel i7 QuadCore der neuesten Generation 8 x 2,9GHz

-

16GB DDR3- RAM

-

2 x 1Gb/s Netzwerkschnittstelle

-

E/A-Modul1 x 240GB SSD mSATA 1 x 1TB HDD SATA

-

Windows 10 Professionell/LTSB 64Bit

-

Acronis Backupsoftware

-

Tastatur

-

Maus

-

Bedientastatur

-

24" Full-HD IPS 16:9 Monitor

-

Maße und Gewicht

-

Kameraeinheit (LxBxH): 39 mm x 39 mm x 40 mm

-

Gewicht ca. 300 g

-

Anschlusswerte und Einstellbedingungen

-

230 V / 50 Hz P1 oder 110 V / 60 Hz

-

Leistungsaufnahme PC: 300 W

-

Leistungsaufnahme Monitor: 120 W

- Temperatur: 5° C - 35° C

- Luftfeuchtigkeit: 10 % - 80 % nicht kondensierend

-

MCS42 SEL AL

kamerabasiertes System